Our Story

Read all about our story below...

JRM Products is today one of the world’s leading processors and producers of liquid hops to the world’s brewing industry. The business was established in 1993 by our founder Dr Jim Seaton and his son Ross.

Jim Seaton was previously a Director at Scottish & Newcastle Brewing Company, which was based at the Fountain Brewery in Edinburgh. He was also the first ever Professor of Brewing at Heriot Watt University, where he was responsible not only for teaching and nurturing many of the world's master brewers, but also establishing the ‘study’ of brewing and our understanding of hops and hop products as we know them today.

Since being established in the 1990s the company has grown considerably, and is still privately owned and run by the family. His son Ross, an engineer and brewing innovator, and Jim's daughter-in-law Janice who brings her business and finance acumen, supported by a knowledgable and passionate team.

The company was initially based in Prestonpans before then moving into the Fountain Brewery alongside Scottish & Newcastle. It has since moved out to a new facility ‘The Hop Plant’ in Haddington, East Lothian, Scotland.

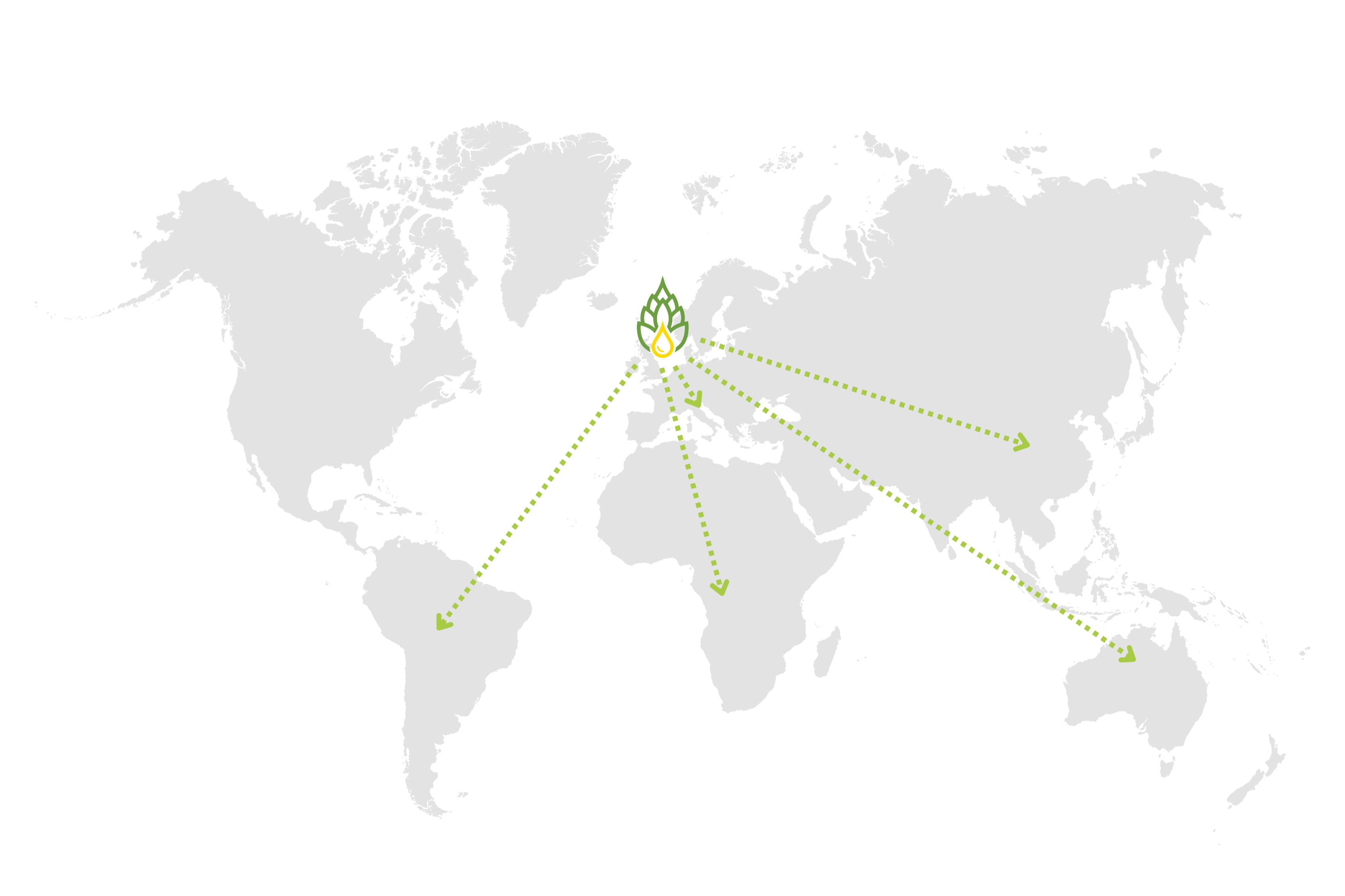

We are a committed team, processing in excess of 200 tonnes of alpha-acids per year, for use by breweries in the UK, EU, Asia, Africa, Australasia and the Americas.

Whilst the true reach of our impact is difficult to quantify, we estimate that of the beers on sale in supermarkets around the world, our products are in 1 of every 8 bottles or cans.

Discover the Global Reach of JRM Products Ltd.

Meet the JRM Team.

Get to know the passionate and dedicated individuals behind JRM Products.

Our Commitment to Quality

At JRM we have always been committed to producing the very best hop products, that the world’s biggest breweries trust in their best-known brands. In 2015 we achieved our inaugural FSSC22000 certification, making JRM one of the first of its kind to operate this model food safely management system. Every single product we produce is sampled and analysed at multiple stages, to ensure the highest standards of quality and consistency. The company was born out of laboratory trials of hop extract techniques, and this approach to innovation remains today. We expanded our laboratory facility in 2014, and the lab is subject to stringent internal procedures and calibrations using International Calibration Standards produced by Labor Veritas in Switzerland. We are also a regular and long-term participant in the (AHA) Ring Analysis hosted by VLB Berlin.